How to Make a Sofa

How to Make a Sofa: A Complete Guide by Mihran Furniture

When it comes to furnishing your home, a sofa is often the centerpiece of your living space. Knowing how to make a sofa can help you appreciate the craftsmanship and quality that goes into each piece. At Mihran Furniture, we pride ourselves on combining traditional techniques with modern innovations to create sofas that are both comfortable and stylish.

Understanding Sofa Construction

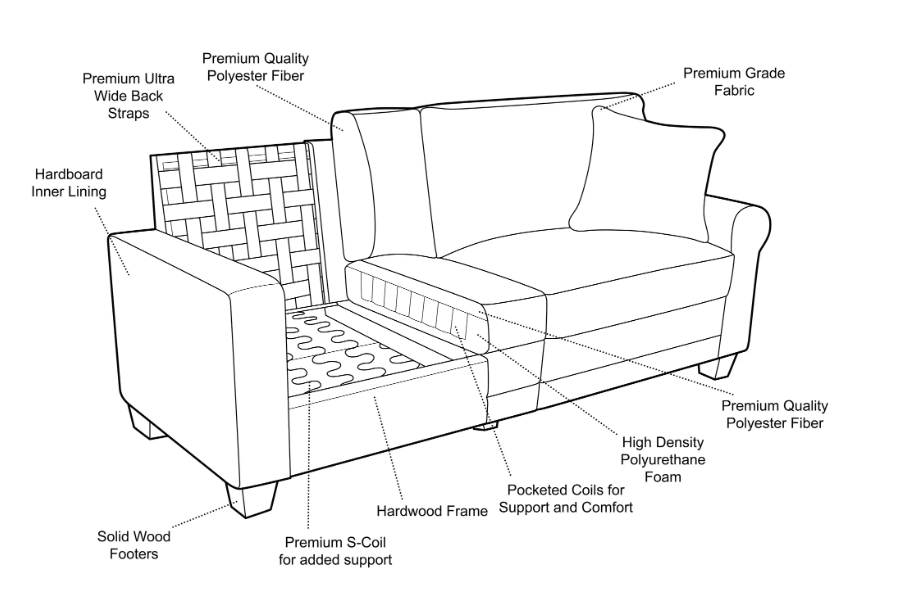

Before you start making a sofa, it’s essential to understand its construction. A typical sofa consists of four main components: the frame, suspension, cushioning, and upholstery. Each part plays a crucial role in the overall durability and comfort of the sofa.

1. Frame: The frame provides the foundation for your sofa. Most high-quality sofas use hardwood frames such as oak, maple, or beech. At Mihran Furniture, our wholesale sofa factory ensures that each frame is carefully measured, joined, and reinforced for long-lasting support.

2. Suspension: The suspension system supports the cushions and provides comfort. Traditional methods include sinuous springs or webbing, while modern sofas may incorporate pocketed coil systems. Proper tension and alignment are key to a comfortable seating experience.

3. Cushioning: Cushions are often made from high-density foam, down feathers, or a combination of both. The type of cushioning affects firmness, durability, and the sofa's overall feel. Choosing the right cushioning is a crucial step when you learn how to make a sofa that balances comfort and style.

4. Upholstery: Fabric or leather covers protect the sofa while adding aesthetic appeal. At Mihran Furniture, we source high-quality materials to ensure longevity and elegance. The upholstery process requires precision, as proper stretching and stitching prevent wrinkles and wear over time.

Step-by-Step Guide on How to Make a Sofa

If you’re a DIY enthusiast or simply curious about the process, here’s a simplified overview of how to make a sofa:

| 1. Design and Planning: Begin with a sketch or blueprint. Determine dimensions, style, and materials. Consider ergonomics, such as seat depth and backrest height. |

| 2. Building the Frame: Cut and assemble the wood frame using joints such as mortise-and-tenon or dowel. Reinforce corners with metal brackets for extra strength. |

| 3. Adding the Suspension: Attach sinuous springs, webbing, or coil systems to support the seat. Make sure the system is evenly distributed for balanced comfort. |

| 4. Cushion Preparation: Cut foam or padding to match the sofa dimensions. Wrap in batting or down to create a soft, luxurious feel. |

|

5. Upholstery Installation: Cover the sofa with your chosen fabric or leather. Stretch tightly and secure with staples or tacks. Pay attention to patterns and seams for a professional finish. |

|

6. Final Touches: Add legs, armrests, or decorative trims. Inspect the sofa for stability, comfort, and appearance. |

By following these steps, you can understand the intricate details behind a sofa’s construction and why quality matters.

Choosing the Right Materials

Material selection is one of the most critical aspects when learning how to make a sofa. Here are some common choices:

- Wood: Opt for hardwoods like oak, maple, or beech for durability. Softwoods are cheaper but less durable.

- Foam and Padding: High-density foam provides firm support, while down or fiberfill adds softness. A combination often works best for comfort and longevity.

- Fabric and Leather: Choose fabrics that are easy to clean and resistant to wear. Leather adds sophistication but requires maintenance.

At Mihran Furniture, our wholesale sofa manufacturer carefully selects materials to ensure every sofa meets our high standards of comfort, durability, and style.

Common Techniques Used by Sofa Manufacturers

Professional sofa makers, including Mihran Furniture, use a blend of traditional craftsmanship and modern technology. Techniques include:

- Hand-Stitching: Adds strength and refinement to seams.

- CNC Cutting: Ensures precision in frame components.

- Steam Bending: Shapes wood for curved designs without compromising strength.

- Automated Upholstery Tools: Speed up production while maintaining quality.

Understanding these techniques helps you appreciate why making a sofa is both an art and a science.

Why Buy from a Wholesale Sofa Factory?

Learning how to make a sofa is informative, but creating one at home requires expertise, tools, and time. Purchasing from a trusted wholesale sofa manufacturer like Mihran Furniture ensures you get:

- Durable frames made from high-quality hardwood

- Comfortable cushioning tailored for long-term use

- Elegant upholstery with precise stitching

- Customizable designs to fit any interior style

Choosing a reliable supplier saves time, reduces risk, and guarantees professional results.

Maintenance Tips for Long-Lasting Sofas

Once your sofa is in place, proper care is essential to maintain its appearance and functionality:

- Leather Sofas: Wipe with a damp cloth, condition monthly.

- Fabric Sofas: Vacuum regularly and treat stains promptly.

- Wooden Frames: Avoid excessive moisture and polish occasionally.

- Cushions: Rotate and fluff to maintain shape and comfort.

Regular maintenance ensures your sofa remains a centerpiece of your home for years to come.

Conclusion

Knowing how to make a sofa provides insight into the craftsmanship, materials, and care required for high-quality furniture. Whether you’re a DIY enthusiast or a design professional, understanding the process highlights the value of a well-made sofa. At Mihran Furniture, our wholesale sofa factory and wholesale sofa manufacturer expertise ensure that every piece we produce combines comfort, style, and durability.